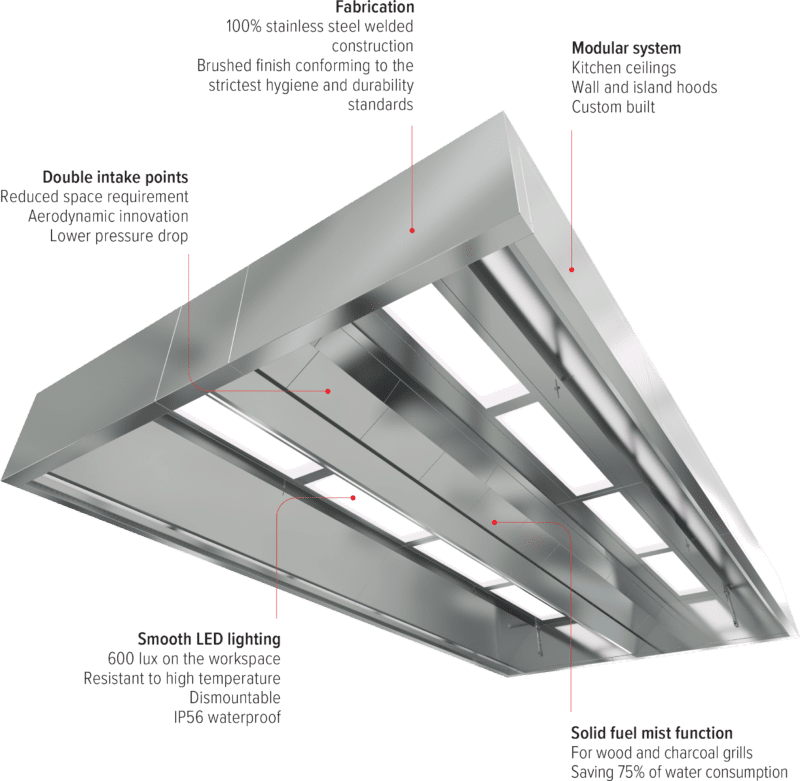

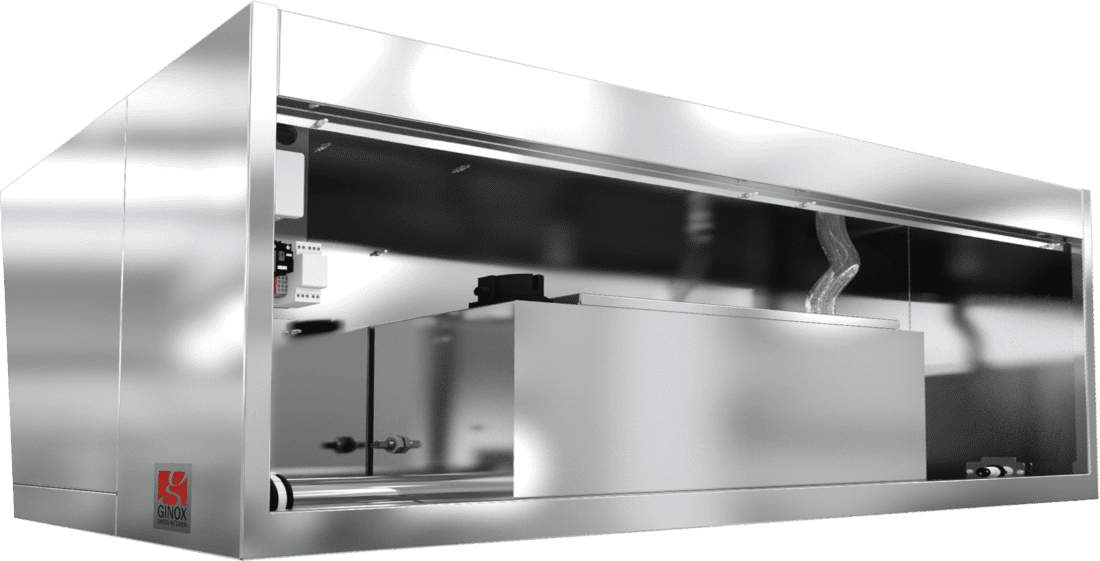

State-of-the-art technology for solutions combining design and functionality

Since the company developed its first generation of self-cleaning hoods in the 70’s, Swiss technology has evolved towards patented EcoClean biotechnological cleaning and clay ball filtration, which removes all grease from the discharged air via the innovative double intake panel system.

The high-efficiency filtration more than halves the annual maintenance costs for the ventilation equipment and substantially improves fire safety.

No more handling filters or maintaining ventilation ducts, and no more grease in the fans.

PerformAir technology is available in all our standard hoods . A range of sizes,options and custom specifications are used to meet the increasingly specific requirements of professional kitchens.

presentation video

Technical specifications

| Material | Stainless steel cage 1.4301, 1.2mm, brushed |

| Lighting | LED panels, 4000K, 600 lux |

| Standard sizes * | Length 1’100 to 10’000mm Width 1’100 to 3’600mm Height 600mm |

| Power supply | 220-240V / 50-60Hz |

| Water usage pressure | 3 bar |

* Custom-made hoods available on request

Advantages

ECONOMICAL

ENVIRONMENTALLY-FRIENDLY

MODULAR

SELF-CLEANING

AUTONOMOUS

AUTOMATIC

PREMIUM DESIGN

Patented clay ball filter

Over 99% of grease particles are filtered by GINOX clay ball filters across a broad range of extraction speeds.

To achieve this level of filtration efficiency, the discharged air is routed in a swirling motion through the porous matrix of the clay balls. This mechanical process eliminates at least 12 times more grease than a standard baffle filter, thanks to the centrifugal forces generated by the matrix.

The fire safety performance of the surrounding ventilation systems and buildings is substantially improved thanks to the high grease particle filtration level.

In addition, the clay ball filters act as a mechanical fire-break.

Because filtration is almost total, the maintenance costs for the ventilation ducts, the fans and the fan filters are reduced to a bare minimum.

The clay ball filtration system installed in PerformAir ventilation hoods works in combination with the automatic cleaning system.

Technical specifications

| Material | Stainless steel cage 1.4301, 1.2mm, brushed finish, clay balls |

| Dimensions (mm) | 450 mmL x 295 mm D x 120 mm H |

| Weight | 8Kg |

| Filter capacity | 800m³/h |

| Pressure drop | 250 Pa at 800m³/h |

Double intake panel for improved efficiency

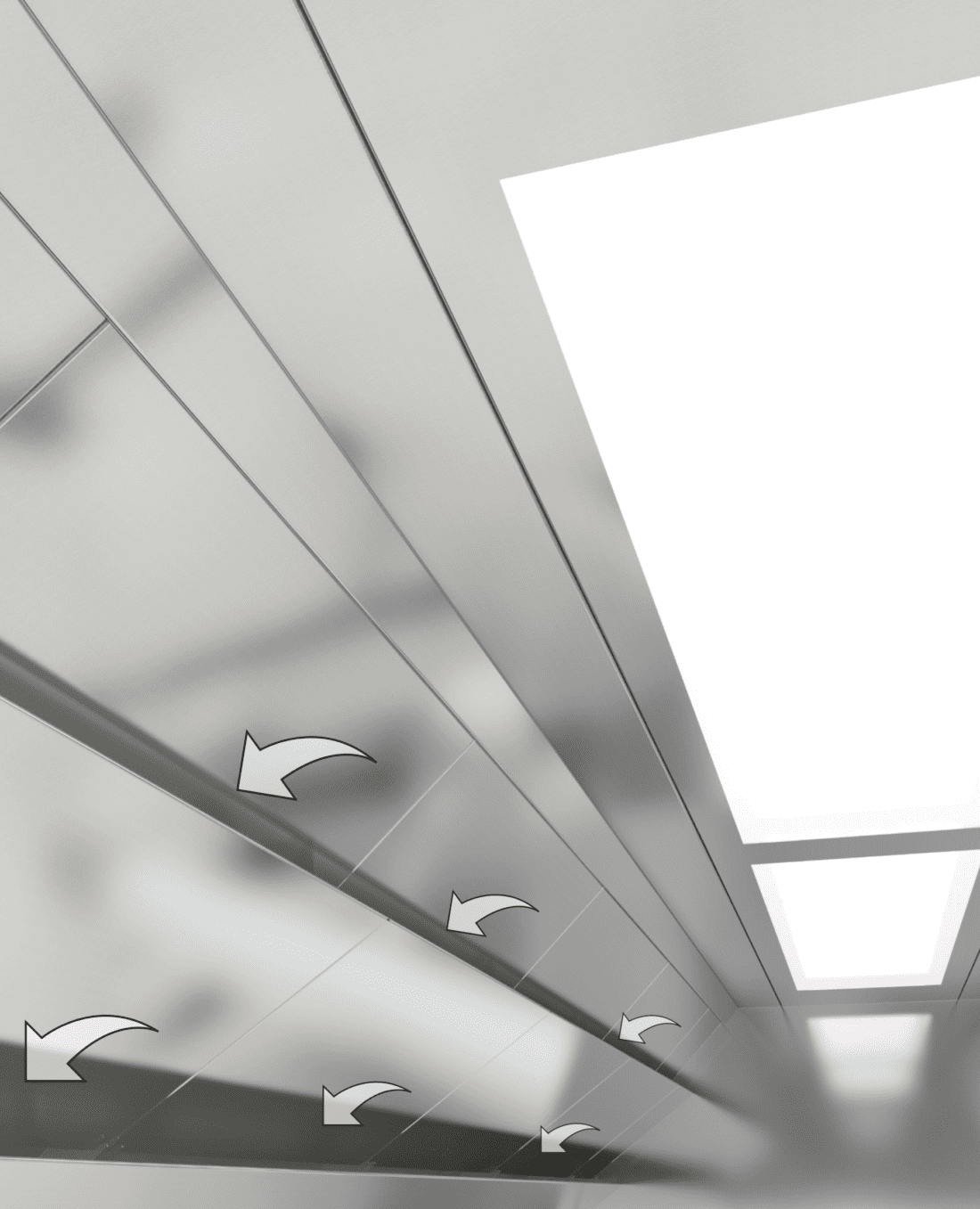

GINOX’s patent-pending double intake panel technology simultaneously captures fumes at both the top and bottom levels of the hood, which means fumes are contained in the hood for a much shorter time.

Double intake technology grants a more compact plenum with a unique and elegant design for show and front of house kitchens open to view, as well as applications for heavy-duty production kitchen.

The double intake optimizes air flow rates to and through the filter, reducing pressure drop.

The double air intake is integrated in the removable self-locking panels to facilitate access to the filtration plenum.

Technical specifications

| Material | Stainless steel 1.4301, 1.2mm, brushed finish |

| Dimensions (mm) | As per hood dimensions |

Self-cleaning system

PerformAir filtration features a unique cleaning technology that uses EcoClean, an enzyme-based product.

EcoClean is a biotechnological solution that breaks down any type of cooking grease. The concentrated solution is mixed with water and sprayed through the nozzle ramps located above and below the clay ball filters inside the hood.

Micro-droplets of the activated enzymes remain inside the filters 24/7, breaking down and dissolving grease continuously. Unlike traditional synthetic detergents, the enzymes are harmless and biodegradable, and can chemically dissolve grease particles without the need for hot water. For environments where the hood is used intensively, a hot-water prewash is added to the cleaning-cycle.

The automatic cleaning cycle can be programmed to activate during the night or at any required time to minimize the impact on kitchen operations.

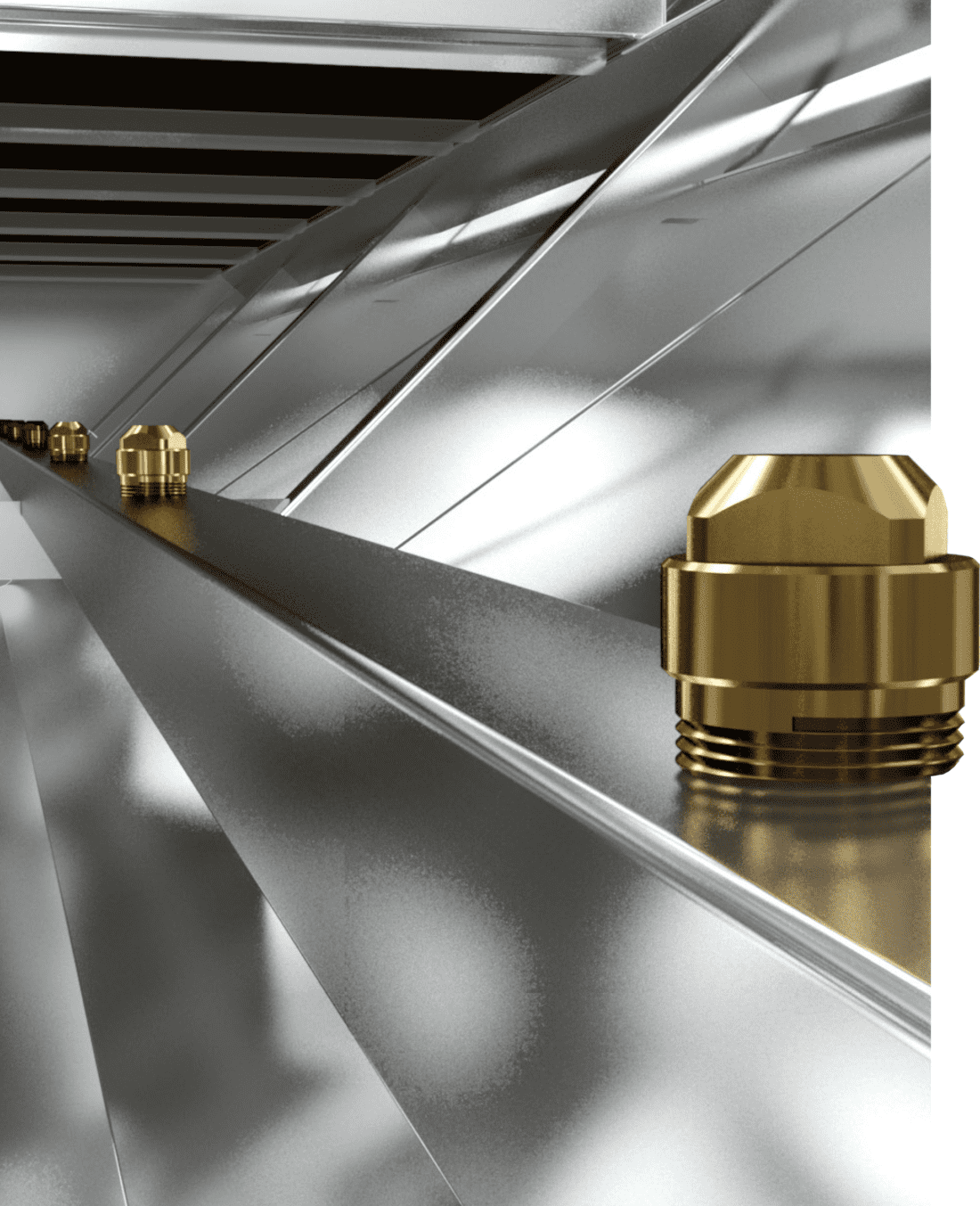

Misting for solid fuel applications

The PerformAir can be converted into a WaterMist hood for wood and charcoal grills, to protect the ventilation system from very hot fumes and sparks.

Misting is intermittent, enabling you to save around 75% on water consumption compared with traditional continuous water curtain hoods. This feature has a big impact on environmental performance and operational costs.

Intermittent misting is made possible thanks to the characteristics of the PerformAir clay filter. Water is sprayed onto the filter, wetting it and enabling it to cool the hot fumes thanks to the effect of water evaporation. The clay ball filter is the perfect spark arrestor.

This feature can be used with the Demand control system to create a Mist-On-Demand hood, saving even more on water costs.

Technical specifications

| Material | Stainless steel 1.4301, 1.2mm, brushed |

| Dimensions (mm) | Depending on the size of the hood |

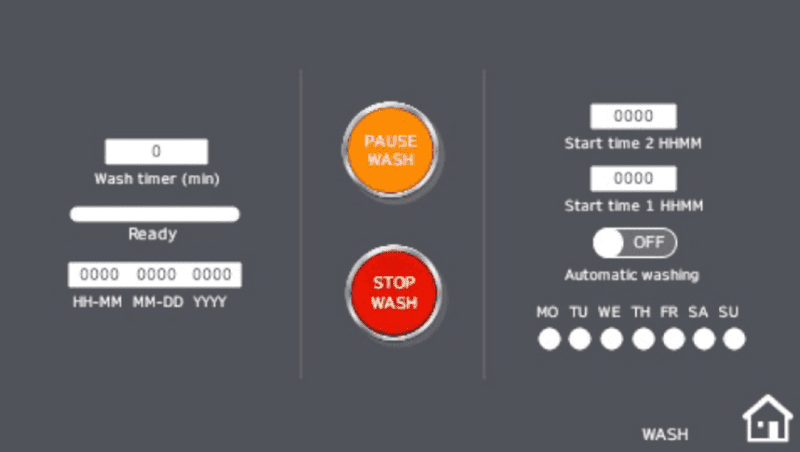

Control cabinet

The control cabinet manages the cleaning process of GINOX hoods. It has been designed to be compact, ergonomic and elegant. Compact to save space in the kitchen, ergonomic for kitchen staff comfort and elegant for customer-facing applications.

For very small kitchens, the system is discreetly integrated directly into the hood’s side panel, without taking up extra space on the kitchen walls. In this configuration, the cabinet is opened by motorized rams.

A key characteristic of the cabinet is its ergonomic operation: a refilling pump for the cleaning product allows the kitchen operator to refill the cabinet directly from the floor without having to lift heavy loads.

The cleaning cycles are fully automated and allow up to 9 hoods to be cleaned with a single cabinet.

The touchscreen interface gives easy access to all information required for operation of the ventilation hood.

The cleaning cycle is easy and intuitive to manage. The control functions can be adjusted on request.

Cabinet technical specifications

| Power supply | 220-240 V / 50-60 Hz |

| Protection rating | IP65 |

| Cleaning product capacity | 60L |

| Dimensions | 1200 mm L x 350 mm D x 500 mm H |

| Water inlet pressure | Dynamic pressure 2-3 bars |

| Water inlet diameter | DN25, 1’’ |

| Water outlet diameter | DN25, 1’’ |

Remote monitoring

The remote monitoring option is used to monitor the cleaning product levels, the cleaning cycle status and the pressure of the PerformAir filters.

It facilitates preventive maintenance and activates automatic cleaning product supply.

The ergonomic touchscreen with attractive color interface enables intuitive navigation for a more user-friendly operation.

ERGONOMIC TOUCHSCREEN ATTRACTIVE COLOR INTERFACE INTUITIVE NAVIGATION

Drain pump system

The GINOX drain pump system evacuates water invisibly from self-cleaning or MistAir hoods.

The solution is typically used in front of house applications for island hoods, where the discharge pipes must be concealed.

The pump evacuates water through the top of the hood, and is discreetly integrated in the side of the hood.

The system is connected to the control cabinet to provide added safety.

Technical specifications

| Power supply | 220-240 V / 50 Hz / 370 W |

| Water flow rate | Up to 160 l/min |

| Discharge height | Up to 9 m |

| Compatible hood models | PerformAir MistAir |

Other options

Lighting

The LED lighting installed in Ginox Swiss Kitchen ventilation hoods ensures ideal and comfortable working conditions for users…

Ecoazur©

The ecoAzur® technology integrated by Ginox Swiss Kitchen allows the hoods to contribute to substantial energy savings thanks to a cooking activity detection system composed of optical sensors

Pulsair

The PulsAir induction technology integrated in the Ginox Swiss Kitchen ventilation hoods reduces the exhaust flow rate by up to 20% while guaranteeing the efficiency of the system.

Laminair

The LED lighting installed in Ginox Swiss Kitchen ventilation hoods ensures ideal and comfortable working conditions for users.

References

Ginox Swiss Kitchen is proud to present a handpicked selection of our references.

Frequently updated, do not hesitate to visit us from time to time to discover new projects.

Nice discovery.